Comprehensive Guide To Aerosol Spray Can Testing

Aug 23, 2024

Introduction to Aerosol Spray Cans

Aerosol spray cans are ubiquitous and used for various products, from personal care items to household cleaners and industrial applications. These cans deliver a fine mist or spray of liquid propelled by pressurized gas, offering convenience and precision. Understanding aerosol spray cans' components, functionality, and testing requirements is crucial for manufacturers to ensure safety, efficacy, and regulatory compliance.

How Aerosol Spray Cans Work

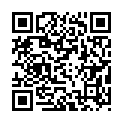

An aerosol spray can consist of several key components working together to dispense the product effectively:

Can Body: Typically made of aluminum or steel, the can body is designed to withstand internal pressure and protect the contents.

Propellant: A pressurized gas or mixture of gases (such as butane, propane, or CO2) that forces the product out of the can.

Product: The liquid or formulation to be dispensed, such as paint, deodorant, or cleaning solution.

Valve System: The mechanism that controls the product's release, consisting of a valve, actuator, and dip tube.

Spray Can Internal Diagram

Types of Valve Systems

The valve system is a critical component of an aerosol spray can, determining how the product is dispensed. Common types of valve systems include:

Continuous Spray Valve: This allows continuous spraying as long as the actuator is pressed, and it is commonly used in products like hairspray and insect repellents.

Metered Dose Valve: This valve delivers a precise, pre-measured amount of product with each actuation. It is typically used for pharmaceuticals and air fresheners.

Tilt Valve: Activated by tilting the actuator, often found in whipped cream cans and some personal care products.

Bag-on-Valve (BOV): A bag is attached to the valve inside the can containing the product, with the propellant filling the space between the bag and the can. This system allows for dispensing the product without mixing it with the propellant, ensuring a consistent spray and reducing the risk of contamination. BOV systems are increasingly popular in medical and personal care products due to their ability to dispense high-viscosity products and maintain product purity.

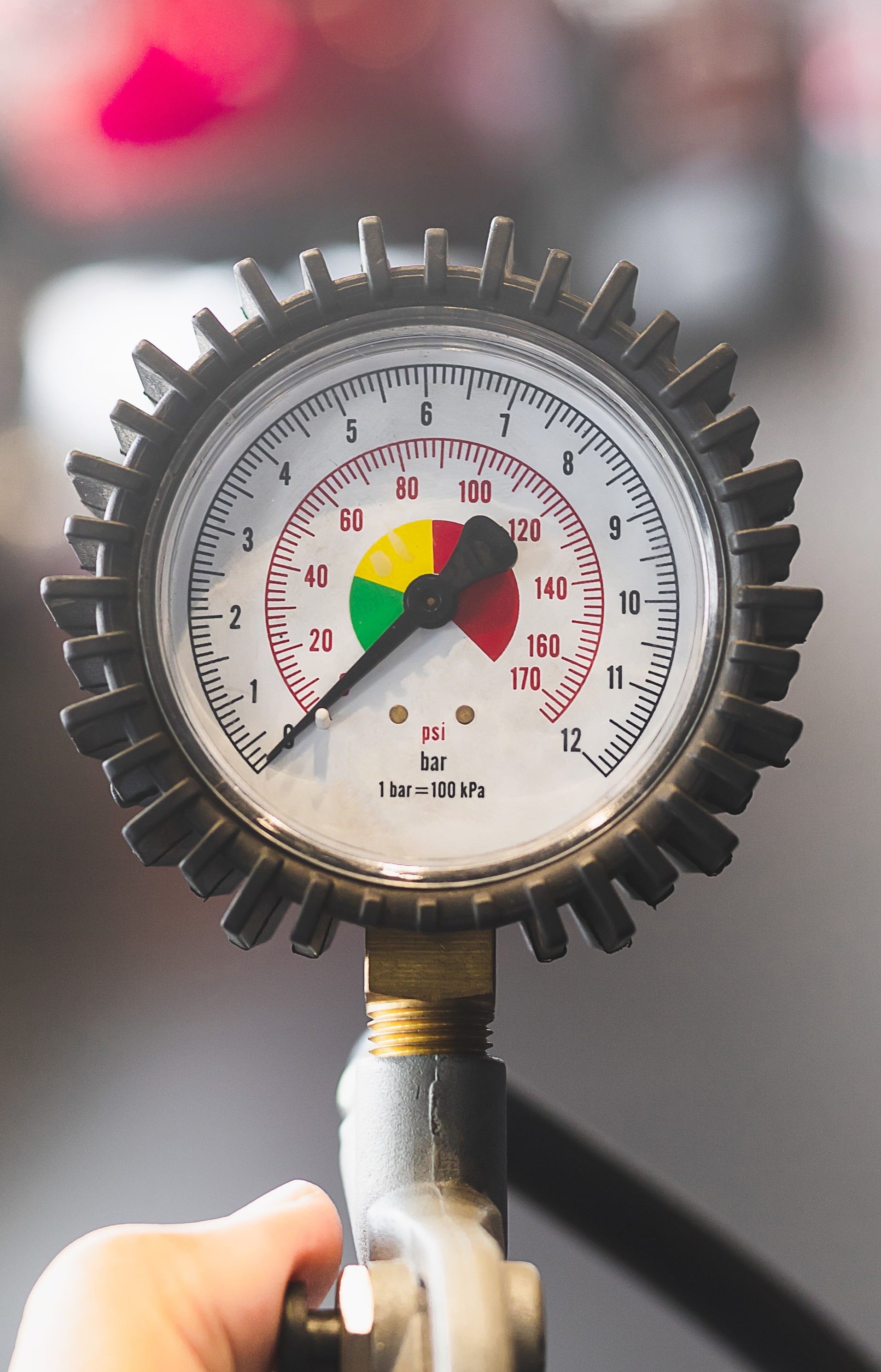

Pressure Gauge For Measuring Internal Can Pressure

Types of Tests Performed on Aerosol Cans

To ensure the safety, performance, and compliance of aerosol spray cans, a variety of tests are conducted:

Pressure Tests:

Burst Pressure Test: Determines the pressure at which the can will burst. This ensures that the can will withstand internal pressure without failure.

Leakage Test: Ensures no leaks in the can or valve system, maintaining product integrity and safety.

Spray Performance Tests:

Spray Pattern Test: Assesses the uniformity and consistency of the spray pattern, ensuring effective product delivery.

Discharge Rate Test: Measures the amount of product dispensed over a set period, ensuring the correct dosage and flow rate.

Valve and Actuator Tests:

Actuation Force Test: Measures the force required to activate the valve, ensuring ease of use.

Valve Functionality Test: Checks the reliability and consistency of the valve operation over multiple uses.

Product Stability Tests:

Stability Testing: Evaluate the chemical stability of the product over time, ensuring it remains effective and safe throughout its shelf life.

Regulatory Guidelines for Aerosol Can Testing

Aerosol spray cans are subject to stringent regulatory requirements for safety and performance. Key regulations include:

U.S. Consumer Product Safety Commission (CPSC):

16 CFR Part 1500: Regulations for hazardous substances, including labeling requirements and testing protocols for pressurized containers. Link to CPSC Regulations

U.S. Department of Transportation (DOT):

49 CFR Part 173: Regulations for transporting hazardous materials, including aerosol cans. It includes classification, packaging, and labeling requirements to ensure safe transport. Link to DOT Regulations

European Aerosol Federation (FEA):

Aerosol Dispensers Directive 75/324/EEC: European regulations for the safety and labeling of aerosol dispensers. Link to FEA Regulations

United Nations (UN):

UN Recommendations on the Transport of Dangerous Goods: Guidelines for safely transporting hazardous goods, including aerosol cans. Link to UN Recommendations

Why Choose ARE Labs for Aerosol Can Testing?

We offer comprehensive testing services for aerosol spray cans, ensuring your products meet all necessary safety and regulatory standards. Here's why you should choose us:

Advanced Testing Facilities: Our lab has state-of-the-art equipment to conduct a wide range of aerosol can tests, from pressure and leakage to spray performance and stability.

Experienced Team: Our experts have extensive experience in aerosol can testing and regulatory compliance, ensuring accurate and reliable results.

Regulatory Expertise: We stay up-to-date with the latest regulations and guidelines, helping you navigate the complex regulatory landscape and achieve compliance.

Customized Solutions: We provide tailored testing solutions to meet the specific needs of your aerosol products, ensuring they perform safely and effectively in the market.

Comprehensive Services: From initial testing to final regulatory submission, we offer a full suite of services to support your product development and compliance efforts.

Conclusion

Aerosol spray cans are widely used for their convenience and effectiveness, but they must undergo rigorous testing to ensure safety, performance, and regulatory compliance. At ARE Labs, we are dedicated to providing comprehensive testing services for aerosol cans, helping you achieve your goals with precision and reliability. Contact us today to learn more about our services and how we can support your aerosol product testing needs.